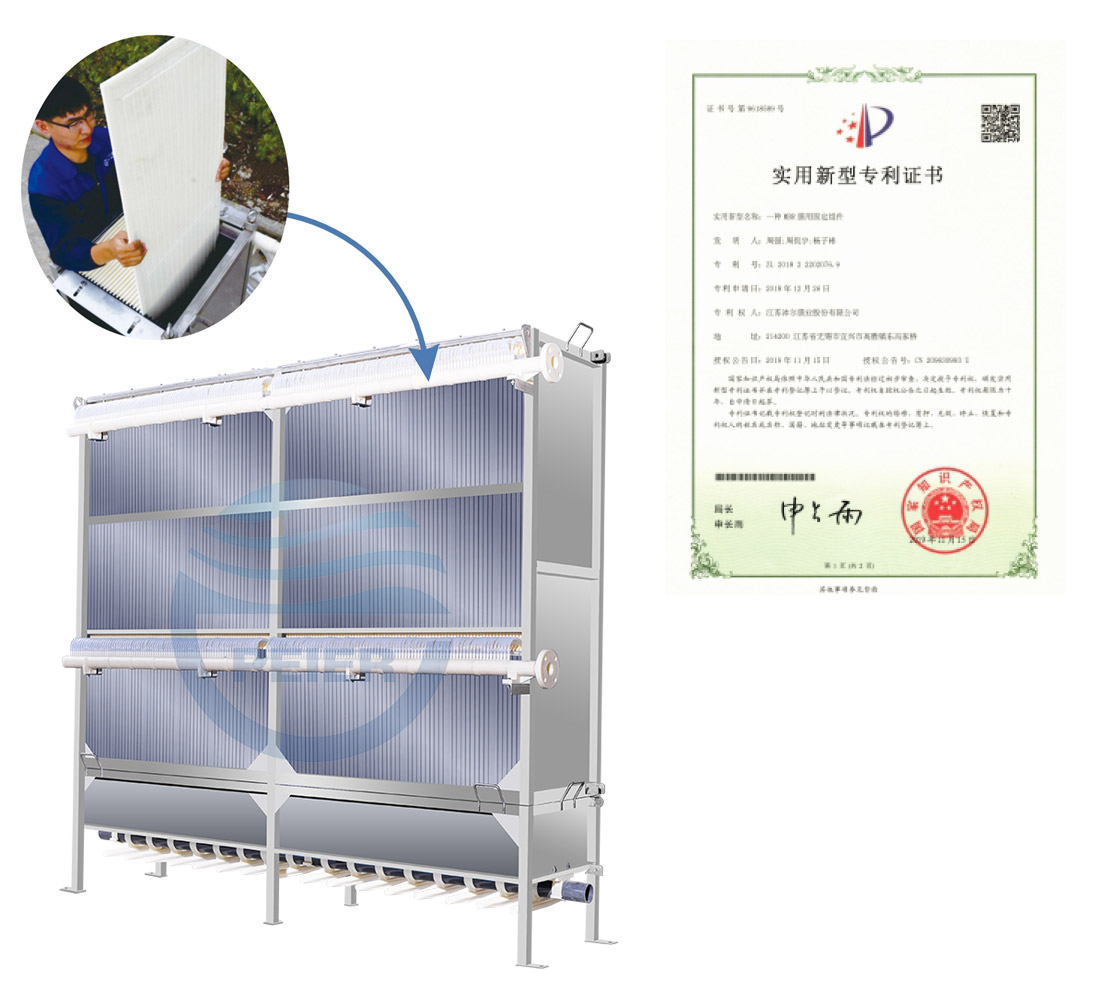

Select 1.5m² Double Nozzle MBR Flat Sheet Element:

● Effective area of 1.5m² Membrane element;

● Two water outlet nozzles are set up at the top and bottom of the side to slow down the vacuum gradient attenuation of high upper and lower dimensions;

● Balance the membrane separation load and greatly improve the separation efficiency;

● Extend the cleaning cycle and reduce the cleaning frequency;

● Guide convex rail is set at the water outlet nozzle side to protect the water outlet at the same time;

The module adopts Peier's unique and advanced double water outlet flat membrane upper and lower extraction and insertion structure. The socket of the flat membrane slot is located at the top of the assembly frame, and the guide convex rail is clamped into the slot. The flat membrane is inserted from top to bottom, which continues the conventional assembly method, and the maintenance of membrane components is faster and convenient.

The side plate adopts an integrated special slot plate, which is packaged as a whole, greatly improving the effect of aeration scouring the membrane surface.

Membrane plate positioning strip with patented technology:

● The wedge-shaped tooth mouth of the upper pressing strip is clamped between the membrane element and the membrane element to eliminate the micro deformation and prestress of the membrane element.

● The relatively added lower pressure strip plays a good role in positioning and vibration isolation of membrane elements, so that the vertical aeration can flush the membrane surface evenly.

| Specifications | Effective membrane area(m²) | Number of membrane elements(piece) |

A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | G(mm) | H(mm) |

| PE150II-20 | 30 | 20 | 386 | 606 | 248 | 604 | 794 | 600 | 2380 | 2470 |

| PE150II-30 | 45 | 30 | 534 | 754 | ||||||

| PE150II-40 | 60 | 40 | 682 | 902 | ||||||

| PE150II-50 | 75 | 50 | 830 | 1050 | ||||||

| PE150II-60 | 90 | 60 | 978 | 1198 | ||||||

| PE150II-70 | 105 | 70 | 1126 | 1346 | ||||||

| PE150II-80 | 120 | 80 | 1274 | 1494 | ||||||

| PE150II-90 | 135 | 90 | 1422 | 1642 | ||||||

| PE150II-100 | 150 | 100 | 1570 | 1790 | ||||||

| PE150II-110 | 165 | 110 | 1748 | 1968 | ||||||

| PE150II-120 | 180 | 120 | 1896 | 2116 | ||||||

| PE150II-130 | 195 | 130 | 2044 | 2264 | ||||||

| PE150II-140 | 210 | 140 | 2192 | 2412 | ||||||

| PE150II-150 | 225 | 150 | 2360 | 2580 | ||||||

| PE150II-160 | 240 | 160 | 2508 | 2728 | ||||||

| PE150II-170 | 255 | 170 | 2656 | 2876 | ||||||

| PE150II-180 | 270 | 180 | 2804 | 3024 | ||||||

| PE150II-190 | 285 | 190 | 2952 | 3172 | ||||||

| PE150II-200 | 300 | 200 | 3150 | 3370 |